I have been asked by a consultant recently that what does the term “Industry 4.0” means to you and how you see its relevance in Indian context. So I thought of putting my views together to express what I make of Industry 4.0 and more.

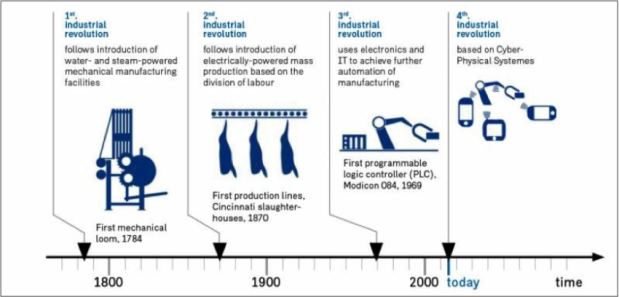

Industry 4.0 is the term coined by Germans putting 4 components together. It comprises of Automation, data transfer and processing in Manufacturing environment, cloud based automated systems and IOT/AOT. It gets supports from cloud based systems and data processing to provide data mobility, consistency and security. If a manufacturing unit has all this incorporated, we call it a Smart Factory (of course a term derived from Smart Phone). At times, the term also get linked to 4th Industrial Revolution which emphasis interconnected systems (IoT) hence Industry 4.0.

Source: DFKI (2011)

With latest modular structures (a place of everything and everything in its place) equipped with automated system will help monitoring floor activities at a factory. An integrated cloud based environment like this will empower decentralized (modular) decision making. This is possible when IoT and automated systems communicate and create synergy with humans in real time. And hence the one link which connects all other 4 components is Human (hence I prefer calling Industry 4.0 and more), without which such an environment cannot not achieve its full potential. Coupled with similar external systems, backward and forward integrated services will create a complete value chain.

If I go back to the original design principles of Industry 4.0, it suggests that there are 4 design principles in Industry 4.0. These principles help manufacturing units to identify and implement Industry 4.0 scenarios. Interoperability, Data Transparency and consistency (SVOT i.e. Single Version of Truth), Technical Support and Decentralized decisions. One can call this Digital Transformation of factories but a real meaning of what Industry 4.0 is missing. Everyone is excited about the term without knowing its real goal. I believe that anyone can achieve this if they stick to the basic four principles. Hiring agencies or expensive consultants resulting expense of millions without a goal will create only negative bottom lines. We must take one step at a time but make sure its a sustainable one. In Indian context, I would say that we are just scratching the surface of it and a genuine appreciation of what transformation requires is lacking. Inadequate IoT infrastructure is amongst the chief obstacles businesses face when launching such initiative. And because labour remains cheap in India, it’s easier for companies to hire people to do jobs that this transformation could otherwise do. Many Indian executives surveyed by the EIU confirm such infrastructure issues are a major impediment to such transformation. One-third (33%) point to a lack of affordable broadband connectivity in this context, and another 35% complain of a lack of technology solutions within their manufacturing units. Human resource talent shortages also hold companies back in their efforts to push this. There is no lack of engineering specialists with the ability to address technical challenges. But once done it will start showing its impacts very early. Latest communication systems coupled with data analytics (AoT) will help reducing the losses due to many manufacturing fugai (manufacturing defects) enabling increase productivity and quality. This also help achieving Total Productive Maintenance (TPM – which requires another 500 words to explain so may be my next blog).

To summarize, Impact in industry 4.0 environment, the decisions are based on processed data and errors does not get multiplied to incur losses but get stopped at its inception only. This processed data (Informative insights) is available in real time with management equipping them to take decision with estimated projections/scenarios. These scenarios are generated using complex algorithm and analytics. As a true impact, real time data gives us projected scenarios and decision being made on factory floors to reduce or stop such future losses or increase the gain.

4.0 concept is aplicable for a few industry as per present condition and work culture in India. Yes, it ofcourse very important to impliment in India for over progress and to come in a row of japan, US and china. In here the owner not take risk to upgrade industry What I have seen in many industry. and also we not have a technically, pratically skilled emp, we are just producing the people who have degree not knowledge.

LikeLiked by 1 person

nice artical at all, we have to go into this.

LikeLiked by 1 person